Nantong Chuangjia new material Co., Ltd. specializes in producing polypropylene BCF yarn, polypropylene BCF yarn, high strength polypropylene yarn, polypropylene double twist yarn, polypropylene plain yarn, polypropylene high strength yarn and polypropylene fiber, polyester fiber, glass fiber, plastic steel fiber, poly Acrylonitrile fiber, lignin fiber series products.

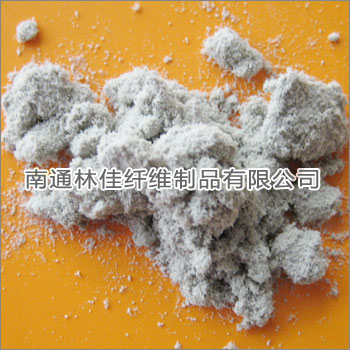

Lignocellulose is an organic flocculent fiber material obtained by chemical treatment and mechanical processing of natural renewable wood. It is a non-toxic, odorless, non-polluting, non-radioactive and environmentally friendly product. Widely used in engineering plastic products, concrete mortar, gypsum products, wood pulp sponge, asphalt roads, filtration, etc., for increasing product strength, improving production stability, preventing coating cracking, improving water retention, and construction suitability It has a good effect of enhancing the adhesion to the surface. Its technical role is mainly characterized by: thixotropic, protective absorption, carrier and filler.

First, the characteristics of lignocellulosic products:

1. Lignocellulose is insoluble in water, weak acid and alkaline solution; pH is neutral, which can improve the corrosion resistance of the system.

2. Lignocellulose has small specific gravity, large specific surface area, excellent thermal insulation, heat insulation, sound insulation, insulation and gas permeability. The thermal expansion is uniform and the shell does not crack; the higher wet film strength and coverage effect.

3. Lignocellulose has excellent flexibility and dispersibility. After mixing, it forms a three-dimensional network structure, which enhances the support and durability of the system and improves the stability, strength, compactness and uniformity of the system.

4. The structural viscosity of the wood fiber makes the uniformity of the processed pre-formed slurry (dry and wet material) stable and reduces the shrinkage and expansion of the system, so that the precision of the construction or prefabrication is greatly improved.

5, wood fiber has a strong antifreeze and heat resistance, when the temperature reaches 150 ° C can be insulated for several days; when up to 200 ° C can be insulated for dozens of hours; when more than 220 ° C can also be insulated for several hours.

Second, lignocellulose application characteristics:

1. Lignocellulose has strong cross-linking and darning function, and its three-dimensional structure effectively reduces the cracking of the mixture.

2, the bio-size stability of wood fiber is very good, improve the product's crack resistance.

3, Lignocellulose itself can absorb 6-8 times its own weight of liquid, can absorb and transport liquid through its own capillary action, once the three-dimensional network structure is at rest, such as cement mortar solidification, lignin fiber can be tightly Adhered to the cement mortar as a sealing layer to prevent the penetration of moisture and rain.

4. The three-dimensional network structure of wood fiber can effectively absorb and attenuate the mechanical energy generated during the curing and drying process, thereby reducing segregation. This allows a thicker plaster to be completed at one time, even under high temperature conditions, the wood fiber has good thermal stability, good leveling and no sag.

5. It can improve the impact strength, fatigue strength and extend the service life of plastic products and concrete products.

6. It can prevent various non-structural cracks caused by plasticity and mechanical shrinkage, segregation and other factors, improve the cohesiveness and water retention of concrete, and improve the workability of concrete.

7. Lignocellulose also has certain temperature resistance, acid and alkali resistance and frost resistance, so it is widely used.

Nantong Chuangjia new material Co., Ltd. mainly produces and sells: polypropylene BCF yarn, polypropylene expanded yarn, polypropylene expanded yarn, polypropylene carpet yarn, carpet BCF yarn, polypropylene twisted yarn, polypropylene double twist yarn, polypropylene high-strength yarn, polypropylene fiber, engineering fiber, polypropylene BCF shaped yarn, polypropylene BCF stranded yarn, polypropylene BCF three-color yarn, polypropylene BCF network yarn, polypropylene BCF three-color yarn, polypropylene BCF shaped yarn, polypropylene BCF Shaped yarn, polypropylene BCF tri-color yarn, glass fiber, plastic steel fiber, polyacrylonitrile fiber, lignin fiber, lignocellulose.